The Future of Scrap Metal Recycling: Advancements, Challenges, and the Role of Cutting-Edge Equipment

1. Introduction

1.1 Importance of Scrap Metal Recycling

Scrap metal recycling is a critical component of modern industrial practices, offering a sustainable way to manage waste and conserve natural resources. Recycling metals like aluminum, steel, copper, and iron reduces the need for mining and processing raw materials, which significantly lowers environmental impact. As global demand for metals continues to rise, the importance of effective recycling practices becomes increasingly clear.

1.2 Overview of Current and Future Trends in Scrap Metal Recycling

The scrap metal recycling industry is undergoing significant changes driven by technological advancements, environmental regulations, and market dynamics. This article will explore the current state of the industry, future trends, and how innovations in recycling equipment can enhance both environmental sustainability and operational efficiency.

2. Current Landscape of Scrap Metal Recycling

2.1 Global Scrap Metal Recycling Market Overview

The global scrap metal recycling market is a multi-billion dollar industry that plays a vital role in the supply chain of various sectors, including automotive, construction, and manufacturing. Despite economic fluctuations, the industry remains resilient due to the consistent demand for recycled metals.

2.2 Key Players in the Industry

Major players in the scrap metal recycling industry include companies like Sims Metal Management, Schnitzer Steel Industries, and Nucor Corporation. These companies are leading the way in adopting advanced recycling technologies and sustainable practices.

2.3 Environmental Impact and Benefits of Scrap Metal Recycling

Recycling scrap metal has numerous environmental benefits, including reducing greenhouse gas emissions, conserving energy, and minimizing the need for landfills. For example, recycling aluminum saves up to 95% of the energy required to produce new aluminum from raw materials.

3. Challenges in Scrap Metal Recycling

3.1 Regulatory and Compliance Issues

Scrap metal recycling is subject to stringent environmental regulations that vary by region. Compliance with these regulations can be challenging, especially for smaller operators who may lack the resources to invest in the necessary infrastructure.

3.2 Technological Challenges

While advancements in recycling technology have improved efficiency, the industry still faces challenges such as the need for more sophisticated sorting and processing equipment. These challenges can limit the effectiveness of recycling efforts and increase operational costs.

3.3 Economic Barriers and Market Volatility

The scrap metal market is highly sensitive to global economic conditions, with prices fluctuating based on demand and supply dynamics. Economic downturns can lead to reduced profitability for recycling companies, making it difficult to sustain operations during lean periods.

4. Future of Scrap Metal Recycling

4.1 Technological Advancements and Innovation

The future of scrap metal recycling will be shaped by continued technological innovation. Advances in automation, artificial intelligence, and robotics are expected to improve the efficiency and accuracy of metal sorting and processing, leading to higher recovery rates and lower operational costs.

4.2 Emerging Markets and Opportunities

Emerging markets, particularly in Asia and Africa, present significant opportunities for growth in the scrap metal recycling industry. As these regions industrialize, the demand for recycled metals is expected to increase, creating new markets for recycling companies.

4.3 Sustainable Practices and Circular Economy Integration

The integration of sustainable practices and the circular economy concept into scrap metal recycling will be essential for the industry's future. By focusing on reducing waste, reusing materials, and recycling more efficiently, the industry can contribute to a more sustainable global economy.

5. Role of Equipment in Efficient Scrap Metal Recycling

5.1 Introduction to Key Equipment: Shears, Balers, and Shredders

Effective scrap metal recycling requires specialized equipment designed to process different types of metals. Key equipment includes metal shears, balers, and shredders, each playing a crucial role in preparing metals for recycling.

5.2 Overview of Hydraulic Metal Shears (Gantry Shears and Alligator Shears)

Hydraulic metal shears, such as gantry shears and alligator shears, are essential for cutting large pieces of metal into smaller, more manageable sizes. These machines are known for their precision and efficiency, making them indispensable in the recycling process.

Gantry Shears

Alligator Shears

5.3 Role of Metal Balers in Scrap Management

Metal balers compress scrap metal into compact bales, making it easier to transport and store. This equipment is particularly useful for handling non-ferrous metals like aluminum and copper, which are often recycled in large volumes.

Metal Balers

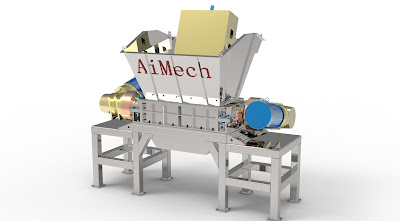

5.4 Importance of Shredders in Metal Processing

Shredders are used to break down metal into smaller pieces, which can then be further processed or melted down for reuse. Shredding is a critical step in the recycling process, as it increases the surface area of the metal, making it easier to separate and recover valuable materials.

Shredder

6. Environmental and Efficiency Benefits of Modern Recycling Equipment

6.1 Reduction in Energy Consumption

Modern recycling equipment is designed to be energy-efficient, reducing the overall energy consumption of the recycling process. This not only lowers operational costs but also contributes to environmental sustainability by reducing the carbon footprint of recycling operations.

6.2 Enhanced Metal Recovery Rates

Advanced machinery, such as high-precision shears and shredders, improves the recovery rates of valuable metals from scrap. This ensures that more metal is reused, reducing the need for raw material extraction and minimizing waste.

6.3 Lowered Carbon Footprint Through Advanced Machinery

By incorporating energy-efficient technology and reducing waste, modern recycling equipment significantly lowers the carbon footprint of scrap metal recycling. This is a crucial factor in the industry's efforts to become more environmentally friendly.

7. Expert Insights and Case Studies

7.1 Expert Opinions on the Future of Scrap Metal Recycling

Industry experts predict that the future of scrap metal recycling will be heavily influenced by technological innovation and sustainability practices. As the industry continues to evolve, companies that invest in advanced equipment and sustainable methods will be best positioned to succeed.

7.2 Case Study: Successful Integration of Advanced Recycling Equipment

A leading recycling company recently integrated advanced shredders and balers into its operations, resulting in a 30% increase in metal recovery rates and a 20% reduction in energy consumption. This case study highlights the importance of investing in modern equipment to enhance efficiency and profitability.

8. Practical Tips for the Scrap Metal Recycling Industry

8.1 Best Practices for Efficient Scrap Metal Collection and Sorting

To maximize efficiency in scrap metal recycling, it's essential to implement best practices for collection and sorting. This includes using advanced sorting technology, training staff on proper sorting techniques, and establishing efficient collection routes.

8.2 Strategies for Maximizing Profits and Minimizing Waste

Recycling companies can maximize profits by investing in high-quality equipment, optimizing their processes, and focusing on high-value metals. Additionally, minimizing waste through efficient sorting and processing can lead to significant cost savings.

9. Future Outlook: The Path Ahead for Scrap Metal Recycling

9.1 Forecasting Industry Growth in the Next Decade

The scrap metal recycling industry is expected to see significant growth over the next decade, driven by rising demand for recycled metals and increasing awareness of environmental sustainability. Companies that adapt to these trends will be well-positioned for success.

9.2 Potential Impact of AI and Robotics on Recycling Processes

AI and robotics are poised to revolutionize the scrap metal recycling industry by automating complex tasks and improving the accuracy of sorting and processing. These technologies have the potential to significantly enhance efficiency and reduce costs.

10. Conclusion

10.1 Summary of Key Takeaways

Scrap metal recycling is a crucial industry that contributes to environmental sustainability and resource conservation. By embracing technological innovation and sustainable practices, the industry can overcome challenges and continue to thrive in the future.

10.2 Final Thoughts and Call to Action

As the global demand for metals continues to grow, the importance of efficient and sustainable scrap metal recycling cannot be overstated. Companies in the industry must invest in advanced equipment and adopt best practices to remain competitive and contribute to a more sustainable world.

FAQs

Q1: What are the main benefits of recycling scrap metal?

Recycling scrap metal conserves natural resources, reduces energy consumption, and minimizes environmental impact by lowering greenhouse gas emissions and reducing the need for landfills.

Q2: What types of equipment are essential for scrap metal recycling?

Key equipment includes metal shears, balers, and shredders. These machines are crucial for processing and preparing metals for recycling, improving efficiency and recovery rates.

Q3: How is the scrap metal recycling industry expected to evolve in the future?

The industry is likely to see growth driven by technological advancements, such as AI and robotics, and an increased focus on sustainability and circular economy practices.

Click here for more details https://www.aimech.top/product/metal-baler/

Comments

Post a Comment